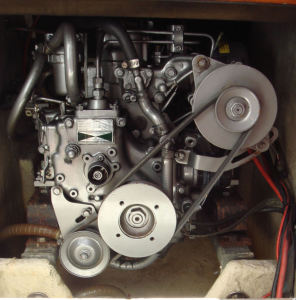

As much as we all love the feeling of the wind in the sails, sometimes there is the need to turn the engine on. Most yachts have diesel engines and it’s a good idea to know your way around them just in case there is a problem.

Give Your Diesel Engine Some TLC

Modern diesel engines are generally very reliable: they need diesel and air to run, lubricant to keep them going, and sea/freshwater to cool them down. If you make sure your diesel engine is well maintained and serviced it should give you many hundreds of hours of happy use.

Modern diesel engines are generally very reliable: they need diesel and air to run, lubricant to keep them going, and sea/freshwater to cool them down. If you make sure your diesel engine is well maintained and serviced it should give you many hundreds of hours of happy use.

On the rare occasion that your diesel engine has a problem, it’s handy to know some simple troubleshooting procedures. Below are our five top tips for basic diesel engine troubleshooting.

But Remember… Safety First!

If you are working on a diesel engine, make sure to remove the engine keys and isolate the engine battery. Wearing protective gloves is a good idea too.

1 – Stay Spick & Span

If you have a clean engine compartment then it is easier to spot leaks or faults.

2 – Tighten Your Belt

Diesel engines will often have the tell-tale sign of black belt dust near the pulleys if you have loose belts. If your belts are too loose then the following problems may occur:

- Your batteries won’t charge due to an inefficient alternator.

- The engine may overheat due to an inefficient water-circulating pump.

You can easily check for these problems by looking at the voltmeter and the engine temperature gauges. Make sure the belts are not too tight as this will increase wear and put excess pressure on the system. Your manual will advise you on the correct adjustment and testing method for your diesel engine.

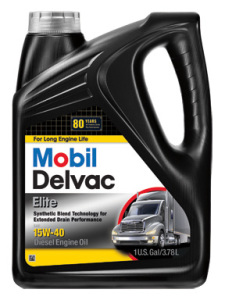

3 – A Slippery Slope

Oil is used to lubricate and cool the internal working parts of your diesel engine. If the engine is functioning properly then the level will remain stable with little change in the short term. Oil is isolated from the water and fuel system by gaskets and seals. If you see that your oil levels drop dramatically then it may indicate a problem with a gasket or seal. Here are some quick ways to check for leaks:

- Look for external leaks around the engine and engine tray – with a clean engine compartment they should be easy to spot.

- If the water cooling system has oil in then it is coming through a seal.

- If blue smoke comes out of the exhaust it may indicate oil leaking into the combustion chamber.

During standard engine maintenance make sure to scrutinise the colour, consistency and texture of the oil. Here’s what you could find out:

- Green or brown oil indicates that the engine is in good condition.

- Grey or emulsified oil means that water is mixed into it – not good!

- Black oil tells you that it is old and that you should consider changing it.

- If the oil smells like it’s burnt then it may be overheating indicating a problem with the engine.

- Particles in the oil could come from a worn engine – get it looked at.

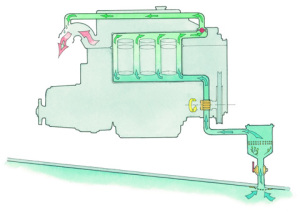

4 – Stay Cool Under Pressure

Most modern diesel engines will have both seawater and freshwater cooling systems. Basically, the seawater circulates around the freshwater and then the freshwater passes around the engine to keep it cool. Here are some simple troubleshooting tips for cooling systems:

- Check if the water intake is out of the water due to the yacht heeling over.

To clear an obstructed drive unit (only on outdrives and sail drives) slow the boat down or reverse slowly to clear the obstruction (usually seaweed or plastic bags).

- Check the seawater intake strainer and clear any debris.

- If the overheat alarm sounds, check the temperature gauges and reduce your revs to reduce the temperature.

- Ensure that seawater is exiting through the exhaust. If it is exiting, then it may indicate there is a problem with the freshwater system.

5 – Don’t Add Fuel To The Fire

The fuel filter is another key system to check if you are having diesel engine issues. Quite simply, the fuel filter separates any water and debris out from the fuel, which then passes onwards through the fuel system to the engine. If you look in the clear bowl on the bottom of the filter you might see collected debris or water. If you do, it is time to change your fuel filter (and maybe your fuel supplier).

RYA Resources

Learn to prevent and solve diesel engine failure! The one day, shore-based RYA Diesel Engine course introduces basic maintenance and engine care to beginners. Rescue call-outs to boaters are most commonly due to mechanical failure; however, engine problems can be avoided by taking simple precautions. Cruisers don’t need to have a detailed mechanical knowledge; although it is good to understand how your engine works, how to keep it healthy by using basic checks and maintenance procedures, and how to get it started again in the event of a breakdown.

On board S/Y Chao Lay, our instructor will teach you the key skills required, not just save you money, but maybe to save your life in the event of an engine failure. Course topics include:

- The principles of diesel engine operation

- The systems and parts of the engine

- Fault finding

- Rectification of common problems

- Bleeding the fuel system

- Changing the impeller

- Routine maintenance and

- Winter lay up procedures.